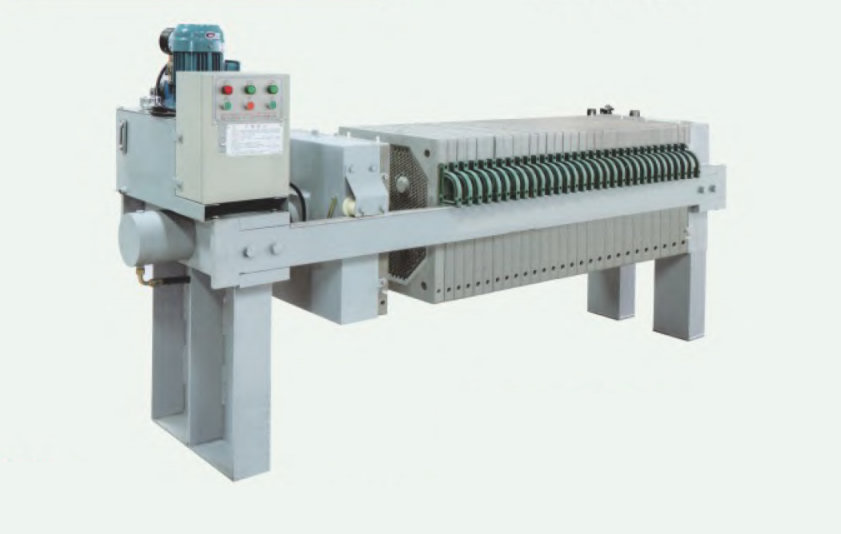

The XMAY630-UBK Chamber Filter Press is a compact and efficient solution for solid-liquid separation. With its robust welded frame, corrosion-resistant design, and high-performance polypropylene plates, it is widely applied in chemical, pharmaceutical, food processing, mining, and wastewater treatment industries. This model is ideal for small and medium-scale operations requiring stable performance, safety, and cost-effectiveness.

Durable Frame Construction

Built with high-strength steel using full-angle welding technology. The frame surface undergoes special anti-corrosion treatment, ensuring long service life.

Reinforced Polypropylene Filter Plates

Plates are made from special formula reinforced polypropylene, molded under high pressure and precision processed. They feature high strength, lightweight design, corrosion resistance, and impact resistance.

Compact Mechatronic Control System

The mechanical, electrical, and hydraulic integration system ensures simple operation, easy maintenance, and minimal footprint.

Advanced Manufacturing Standards

Produced with high-standard processes and technologies, the XMAY630-UBK offers stable operation, reliable structure, and durability, making it an ideal solid-liquid separation device.

| Filter Area (m²) | Plate Size (mm) | Plate Thickness (mm) | Chambers (pcs) | Cake Thickness (mm) | Total Volume (L) | Center Distance (mm) | Working Pressure (MPa) | Motor Power (kW) | Machine Size (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 630×630 | 50 | 13 | 25 | 100 | 1520 | ≤1.0 | 2.2 | 2010×830×1610 | 1150 |

| 10 | 630×630 | 50 | 17 | 25 | 125 | 1670 | ≤1.0 | 2.2 | 2160×830×1610 | 1200 |

| 12 | 630×630 | 50 | 19 | 25 | 150 | 1820 | ≤1.0 | 2.2 | 2310×830×1610 | 1250 |

| 16 | 630×630 | 50 | 26 | 25 | 200 | 2170 | ≤1.0 | 2.2 | 2660×830×1610 | 1340 |

| 20 | 630×630 | 50 | 32 | 25 | 250 | 2470 | ≤1.0 | 2.2 | 2960×830×1610 | 1430 |

| 25 | 630×630 | 50 | 40 | 25 | 312 | 2870 | ≤1.0 | 2.2 | 3360×830×1610 | 1540 |

| 30 | 630×630 | 50 | 48 | 25 | 375 | 3270 | ≤1.0 | 2.2 | 3760×830×1610 | 1670 |

Chemical Industry: Filtration of pigments, dyes, and chemical slurries

Food & Beverage: Juice clarification, starch, sugar processing

Pharmaceuticals: Separation of fermentation liquids, herbal extraction

Mining & Metallurgy: Tailings treatment, slurry dewatering

Environmental Protection: Sludge dewatering, wastewater treatment